A History of Innovation

1898: Wm. T. Burnett was established in Baltimore as a trading company for cotton linters. It evolved into a manufacturer of cotton batting and felt for the furniture and bedding industries, and quickly earned a reputation for quality, dealing in high-end India cotton. During WWII, the company was a designated government supplier of kapok, an important material used in life preservers.

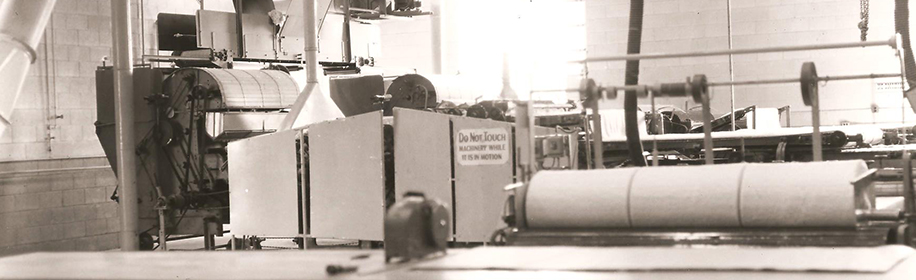

1950s: Venturing into the flexible polyurethane foam manufacturing business in 1954, Wm. T. Burnett became the first U.S. licensee of Mobay Technology, a joint venture of Bayer and Monsanto. The company’s current headquarters and site of the original plant in Baltimore was the location for the first continuous pouring machine for flexible polyurethane foam in the world. The massive equipment had a reciprocating pour head and laid the pre-polymer mixture into waxed pans that traveled beneath the pouring head on a conveyor, a true innovation of the time. In the mid-1950’s, the Statesville, North Carolina plant was opened to better service customers in the furniture industry.

1960s: In 1964, synthetic fiber was introduced to the Statesville plant, which had previously only converted cotton. Starting in 1965, polyester was used to form filling batt.

1970s: Continuous filament fiber was introduced in the early 1970s, and the company invented and manufactured equipment to blow CF fiber into furniture cushions.

1980s: In 1985, Wm. T. Burnett began as one of the first producers of “low melt” or thermal-bonded fiberfill. The company also pioneered and patented the process for densified polyester fiberfill with weights and thicknesses that could be used in mattress cores, outdoor furniture and commodity foam replacement. Continuing throughout the 1980's, new technologies were implemented at the company’s expanding plant operations, including new bonding lines, high speed cross lappers with needle punch capabilities, finishing looms, and ovens for high-loft bonding.

2000s: Beginning in the fall of 2004, Wm. T. Burnett became one of the first manufacturers to successfully produce a high-loft barrier made of modified rayon.